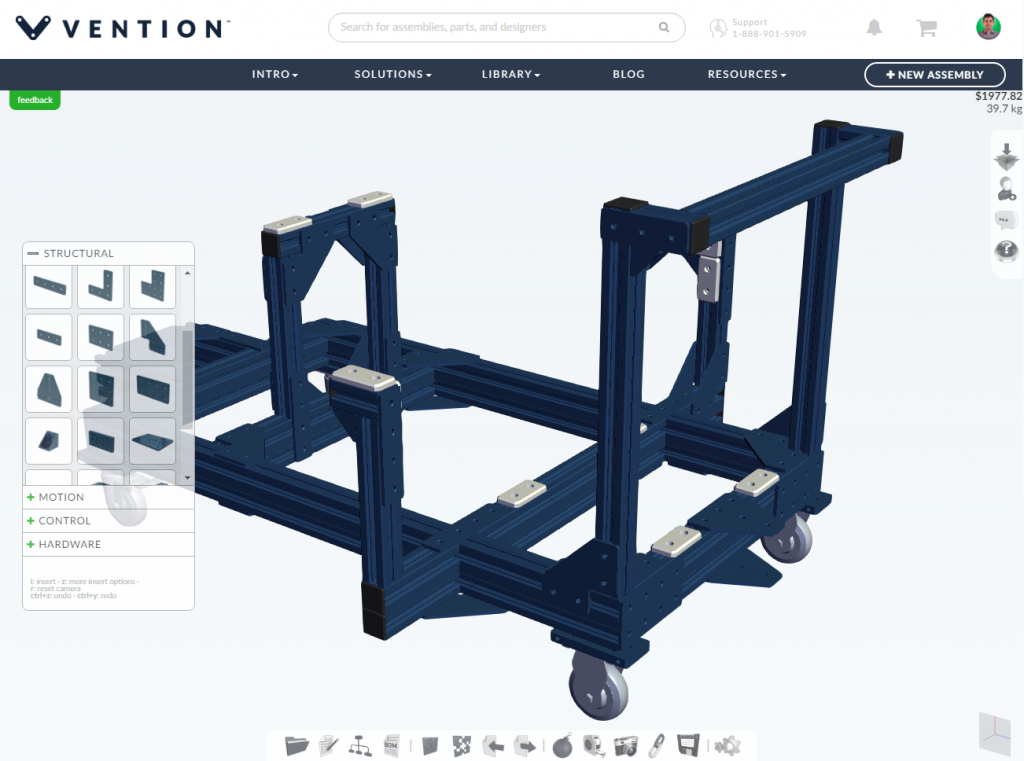

Vention wants to democratize industrial design. By incorporating artificial intelligence in its platform, this Montreal startup is working to make the 3D design experience significantly easier and faster — not to mention more affordable — for smaller businesses working on lean automation and product validation.

The company allows users to design and build custom machines from a web browser, and includes a library of industrial-grade parts. Custom designs are shipped within three days.

“With the help of artificial intelligence, we are paving the way for significant democratization of mechanical engineering,” said CTO Max Windisch. “We want to enable design-savvy individuals who never used CAD software, to 3D design industrial machines and prototypes. Similar technology democratization in web development (i.e. WordPress, Wix) were complete game-changers; we are creating the equivalent for machine design.”

BetaKit spoke with founder and CEO Etienne Lacroix about today’s beta launch, the genesis of the company, the source of their inspiration, and their plans for the future.

How did you come up with the idea for Vention? Was it a result of working in the industry and feeling there was a gap, or something that just struck you as a great product to build?

I started my career at 19 years old, designing custom industrial equipment the “old way” for the aerospace industries. I was well aware of the pain points across the entire value-chain (from design, to procurement, to assembly). My four years at General Electric and five years at McKinsey working in the industrial context also helped me develop a thorough understanding of this space.

Fun fact: I was in Italy in 2014, walking in Florence with my wife when it all clicked in my head. I pretty much started to work on the business plan next day.

So what’s your revenue model? I understand that it’s free now — will this become subscription-based platform?

The design software will remain free as we generate revenue from the hardware that we sell. For example, [if] you want to design a custom crane, you can use our entire design platform for free and generate as many design versions as needed. We generate revenue if you decide to purchase your custom crane based on Vention’s components. You would then receive your product within a few days, ready for assembly.

Does a professional engineer licensed by the province sign off on the drawings that are created with your software before you manufacture them?

Keep in mind that we aren’t a manufacturer of any parts of machines. Because we are a distributor of industrial parts that operate a proprietary 3D machine builder, like other 3D design software, we don’t replace the engineering judgement. Most companies have very explicit guidelines about when a professional signature is required. Those processes remain the same.

Are there any other companies working in this space already, or are you the first?

Some companies are doing great things in 3D design software, others with industrial hardware; but we are the only one trying to eliminate the frontier between the “software” and “hardware” worlds. We hope that by doing this, we will democratize mechanical engineering in a significant way.

What’s the AI background of your team?

Our AI technology relies on the same foundations of geometric reasoning as typical CAD, but emphasizes speed and ease of use (as opposed to exhaustive treatment). One of the main ideas in place today is the generation of a search space for ways of combining two parts, and a ranking algorithm to prune that search space and present options that a user can select very quickly, fitting the current state of the assembly as much as possible. Another aspect, analogous to the concept of the semantic web, is to leverage the meta-data that we own about each part of our catalogue.

We wanted to make the 3D assembly of complex machines extremely easy for non-professional users. – Etienne Lacroix, CEO

In the near future, this will allow us to provide powerful classification and search capabilities for patterns recognized in the assemblies that our users produce. We’re also considering further enhancing our ranking algorithm (which presently relies mostly on geometric reasoning and special heuristics) with the fruit of applying machine learning to the types of assemblies generated by our users.

Here I need to praise my CTO, Max Windisch. Max is an accomplished classical musician and like some top-performing classic music professionals, he is also extremely strong in math, and computer science. Max started to code at seven years old and has an impressive track record in 3D and cloud architecture. Max previously worked for SoftImage, Kaydara, PI, VM Ware, Pivotal, and more recently GE (in their IoT group).

Why did you choose to build a product with AI?

We didn’t start with AI — we started with a problem to solve and realized that AI was the way to go, two months into the development. We wanted to make the 3D assembly of complex machines extremely easy for non-professional users. We started to explore various “3D constraint solvers” and how we could further automate them to improve ease-of-use for our users. The more we progressed, the more it looked like AI. We were reluctant to call it AI at first, as we thought they were just “clever algorithms,” and don’t necessarily leverage deep neural networks, but at some point we needed to call a “cat” a “cat.”

Vention recently raised a pre-seed round led by Boston-based Bolt, and Toronto-based Real Ventures. They are participating in the 2016-2017 cohort of the Creative Destruction Lab of the Rotman School of Management at the University of Toronto, one of Canada’s leading accelerators for the commercialization of science-based companies.

Image via Vention